Art to walk on

Epoxy. Concrete. Coatings. Resin floors.

Innovation. Quality.

Durability.

Durability.

We meet the highest standards in the pharmaceutical industry

Fresh, creative walls

Microcement. Stucco. Venetian plaster.

Previous slide

Next slide

KJ Trading

is a leading company in the flooring systems industry in Puerto Rico. It offers a wide range of flooring systems, surface preparation, moisture mitigation, corrosion control, and wall systems.

Our versatile range of commercial, industrial and residential flooring and wall solutions combine tested technologies with industry-driving innovation.

Mission

To provide our customers with high performance products, quality service and superior craftsmanship in the flooring and wall systems industry.

Vision

To expand and strengthen

KJ Trading as a leading brand in the flooring systems industry.

Services

- All

- Decorative Flooring

- Floor Treatment

- Industrial Flooring

- Wall Systems

Concrete Restoration

Structural concrete restoration consists of repairing deteriorated concrete and rusted reinforcing steel to bring the structure back to its original specifications and condition.

Learn More →

Flakes

TORGINOL® Polymer ColorFlakes™ are specially formulated paint aggregates used to enhance the aesthetic and ergonomic qualities...

Learn More →

High Build

Designed for industrial floors exposed to heavy foot and rubber wheel traffic, and chemical abrasion resistance and adhesion, this flooring system provides...

Learn More →

High Build Troweled Mortar

This is a 1/8″-1/4″ high build protective resurfacing system utilizing an epoxy and silica aggregate mortar, high build grout and seal coats.

Learn More →

High Chemical Resistant Coatings

In manufacturing industries exposed to harsh chemicals and severe temperatures, a vinyl ester or an epoxy novalac product is recommended.

Learn More →

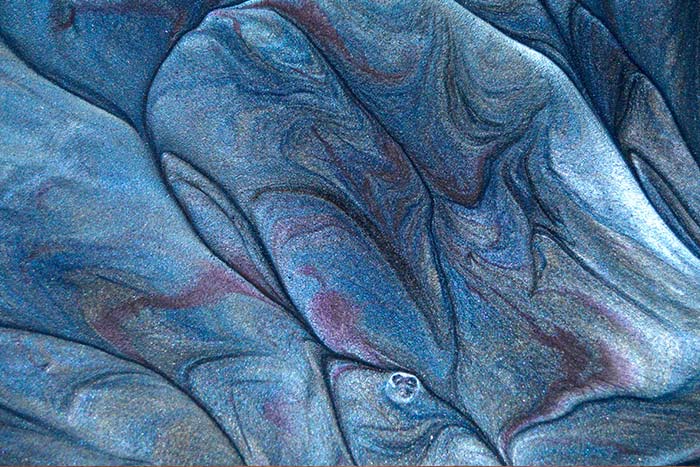

Metallic Pigments

Enhance your environment with the shimmering play of light and color.

Learn More →

Mica Flakes

TORGINOL® MicaFlakes™ make resinous flooring glisten with natural crystalline beauty.

Learn More →

Microcement

Microcement is a decorative, composite coating based on cement, water-based resins, additives and mineral pigments.

Learn More →

Moisture Mitigation

Moisture mitigation systems eliminate the movement of water vapor into the flooring system.

Learn More →

Quartz

Redefining toughness with an enhanced focus on combining durability with design and functionality.

Learn More →

Surface Preparation

Surface preparation is key to achieve a successful flooring installation.

Learn More →

Terrazzo

Terrazzo flooring is one of the most aesthetically and popular flooring systems.

Learn More →

Thin Mil Coating

Designed to provide light reflective and a chemical resistant finish to your floor.

Learn More →

Traffic Deck Coating

Moisture mitigation systems eliminate the movement of water vapor into the flooring system.

Learn More →

Venetian plaster

Venetian plaster is a versatile design material. It is made with durable materials such as lime, cement, sand, marble dust and pigment.

Learn More →

Wood Chips

Natural WoodChips™ are manufactured from a range of premium quality natural and engineered wood veneer species. Reclaim your environment...

Learn More →